FOCUS SMCs is a world leading manufacturer of soft magnetic composite materials (SMCs). we can help electric machines manufacturers make: smaller, lighter, durable, reliable, efficient,less end-costs products. Our SMCs have been widely used on electric motors, inductors, transformers, compressors, pumps, actuators etc. From evaluating drawings to moulds designs, and moulds production, SMCs products manufacture and testing are all realized in our factory. So 98.7% of delivery time can be guranttened. A series of presses from 50tons to 1,500tons can fit many kinds of requirements. Our complete testing system including metallographic microscope, digital Teslameter, bush Hardness Tester etc. can guarantee high quality. Adhere to the spirit of laser, we only specialize in 1 meter wide business (only SMCs), and we specialize in 10,000 meters deep in soft magnetic composites products field.

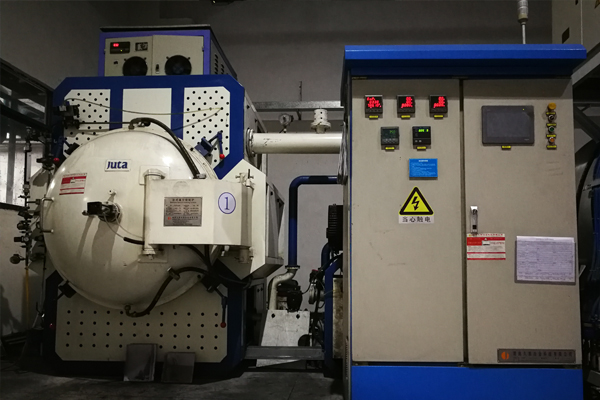

Focussmc is like a laser, we focus on the reserch and development of SMC. Focussmc has accumulated more than ten years of experience in soft magnetic composite materials, advanced production equipments, active and excellent employees, to ensure that we can provide our customers with high-quality and reliable products, we have passed IATF16949 certification.

.jpg)

Social problem:

Global warming caused by the large industrial consumption of energy is one of the biggest environmental challenges in the worldwide. According to the United States Environmental Protection Agency (EPA), various motors consume more than half of the electricity used in manufacturing. And, if we concentrate on industrial energy-related carbon dioxide emissions, they exceed 1,300 million tonnes per year in the United States alone. Industry accounts for nearly a quarter of the country's greenhouse gas emissions.

According to the International Energy Agency (IEA), electric motors and systems account for more than 40% of global electricity consumption. They also claim that "global energy-related CO2 emissions remained at 31.5 Gt in 2020, contributing to CO2 reaching its highest-ever average annual concentration in the atmosphere of 412.5 parts per million."

Leaders in industry and manufacturing have the opportunity to embrace sustainability and reduce energy consumption by implementing more efficient motor systems. Experts estimate that global adoption of high-efficiency motor systems could reduce electricity consumption by up to 10%.

What does soft magnetic compsite bring for human beings?

Metal powder(PM) innovation gives vast open doors, not only help our clients to reduce their costs and energy consumption, but also help them to get benefits from new and better technology. They can provide cheaper and higher efficiency products for their customers.

Instances of how SMCs can give lower creation costs:

Size and weight decrease of parts

Decrease of the complete number of parts in the last application

Less requirement for machining

Low piece rate in assembling

Focus New Material is a leading global supplier of precision soft magnetic composite components (SMC) for the electronics industry. We focus on the research, design and production of high-quality SMC cores. Helping electric machines manufacturers to make high performance, more energy efficient, and more sustainable e-motors is our ending-aim. Our products are widely used in motors, inductors, transformers, compressors, pumps and other equipments.

Focus social responsibility:

As one of the globally leading providers of metal powder solutions, we feel a duty to initiate and lead the sustainable transition necessary to meet future challenges and rapidly changing market demands.

We are convinced that metal powders can contribute to sustainable development and thereby solve many of society's pressing challenges, such as resource scarcity, shortage of clean water and conversion to renewable energy use. Using powder metallurgy, complex parts that are close to net-shape, and with good part-to-part uniformity, can efficiently be mass-produced with few production steps. This leads to high material utilization, low energy consumption and reduced waste.

Focus helps electric motors and inductors manufacturers to produce high-performance, lightweight and fast-response products, to keep a sustainable earth for our future generations.

Focus strategy

We use 5% of the annual profit in equipments updating, personnel training, material research and development, to design more suitable soft magnetic composite cores to solve the problems faced by motors and inductors with smaller size, lighter weight, lower cost, and faster response.