Soft magnetic composite (SMC) challenges conventional material like electrical steels and soft magnetic ferrites in applications with substituting magnetic fields. As the market potential is enormous, this is an interesting region for the P/M industry. By using the elements presented by the actual material as well as the P/M forming strategy new aggressive electromagnetic designs can be understood.

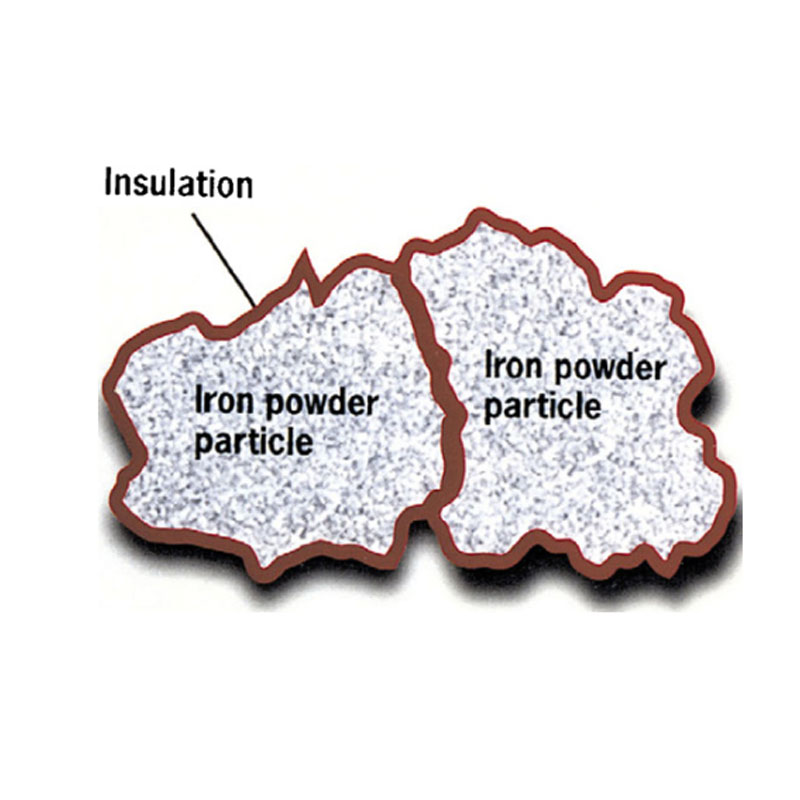

SMC-materials are fundamentally iron powder particles isolated with an electrically insulated layer as displayed in Figure 1. The powder metallurgy (P/M) process has for long time been utilized to produce SMC parts for high frequency inductor applications. These SMC materials comprise by and large of iron particles conveyed in grid of natural materials.

figure 1.

Because of the air gap and great high frequency cores made of iron based SMC materials is the most cost efficient solution for inductive parts in different channel and power change applications.

As of late the gathering of SMCs has been extended by the presentation of new materials. These materials contain no organic matrix that set limitations on the handling conditions. This makes it possible to produce parts with much higher saturation induction, permeability as well as lower hysteresis losses. Subsequently, SMC's are presently likewise an alternative to lamination steel sheets in applications in the low to medium frequency, for example, fast switching solenoids, sensors and rotating machines. As the innovation actually is fairly youthful applications, material, process and application improvement is progressing at a fast.

Essentially there are three primary highlights presented by the innovation.

1. 3D-flux carrying capability.

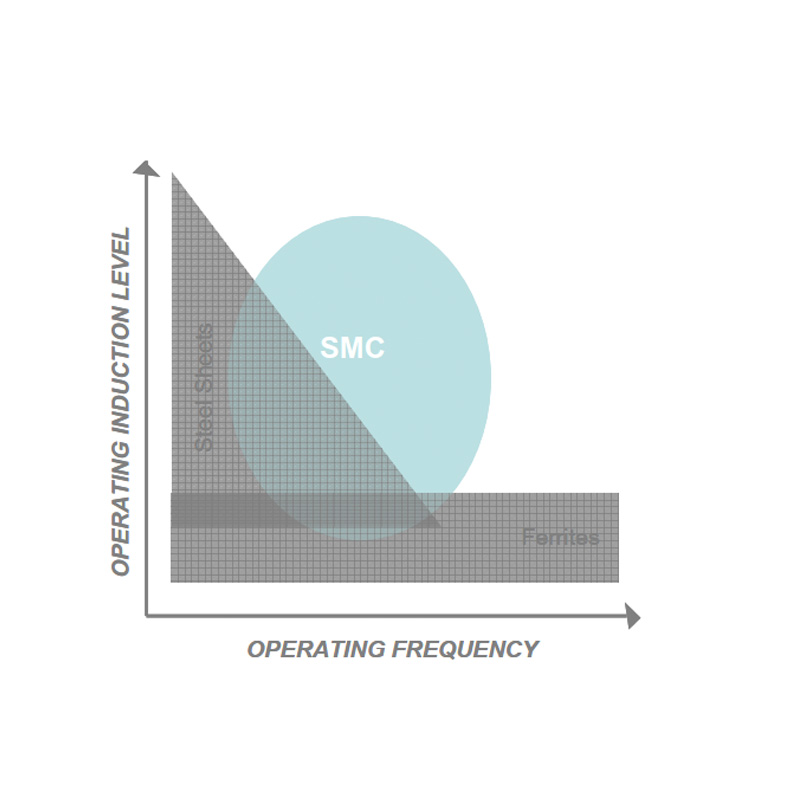

2. Unique combination of low eddy current losses and magnetic saturation. Figure 2 shows the position of SMC compared to traditional materials.

3. Cost efficient production of 3D-net shaped component by the P/M process.

figure 2.

ELECTRICAL MOTORS

As the usage of electric laminations for electrical motors is several times bigger than the market for sintered components, this is an interesting objective for the P/M industry. In any case, it is trying as material, plans and assembling has been optimized for a 2D flux over an extensive period of time. A "drop-in" alternation of a lamination steel sheet by a SMC will bring about best case in an equivalent execution at a similar expense. One exception could be motors working at high frequency where a direct alternation might bring about certain advantages. In any case, the way to progress is tracked down in using the 3D capacity of the material. The opportunities for the designers to use new structure with shape, winding and gathering arrangements past the present principles opens up for advantages, for example, decreased size and weight, less parts, reduce size and lower cost

A 3D design can be taken on for all ordinary motors topologies. For example a 3D-designed. All universal motor can essentially reduce the Cu-wire and increase the performance of the application. In spite of this it has been shown to be challenging to market SMC in both universal and induction. These motors work at low net frequency which allows them to use thicker and cheaper electrical laminations.

Besides, in these motors, the reluctance in the magnetic circuit is low as the air gaps are little and there are no permanent magnets. SMC has a lower permeability than lamination steels and this impacts the magnetic flux in the circuit and should be compensated by adding more iron.

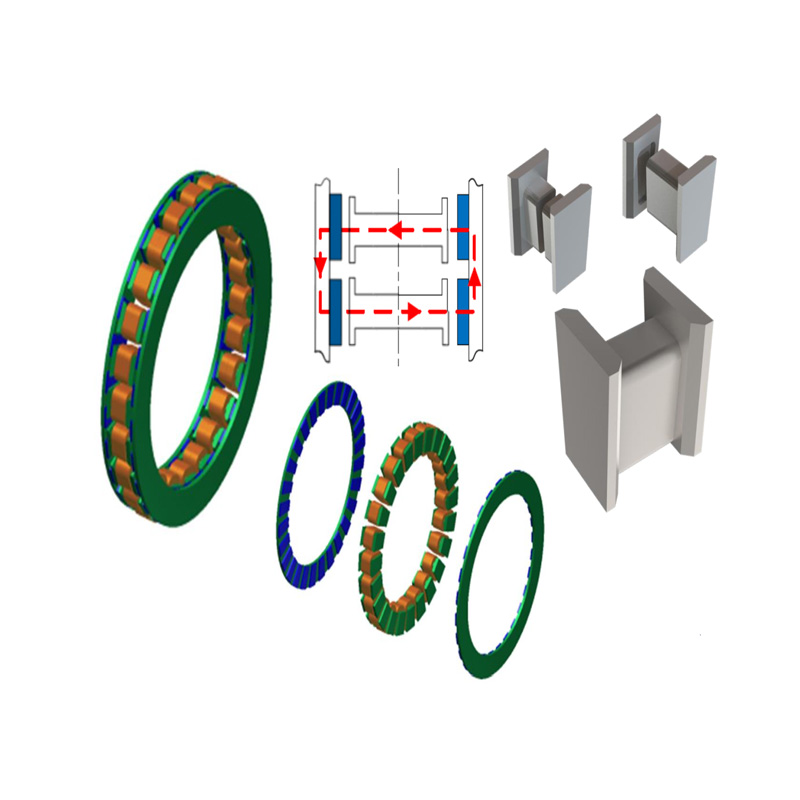

The pattern toward high productivity extremely permanent magnet motors, for example, variable speed expands the modern for the advanced SMC materials. Motors can be intended to work at higher frequencies as a regulator is required. The permanent magnet has an extremely impact of the reluctance which restricts the impact of the lower permeability of the SMC material. A fascinating motor geography for SMC is the axial flux motors. This has effectively been shown in the existence vehicle project in UK where a superior performance axial flux machine was intended for a traction application. Please check the figure 3. shows

figure 3.

Perhaps, the most suitable motor topologies for SMC are transverse flux machine (TFM), claw pole, axial flux motors, linear machines. The Claw pole/TFM machines have a 3D flux path and are thusly challenging to make with laminations

The most striking benefit by using SMC in linear machines is according to assembling perspective. It is obviously delineated in the following picture that the quantity of parts can be decreased obviously and gathering improved by changing from electrical laminations to SMC, and the performance can be improved. We can see the result easily in figure 4.

figure 4.

MATERIAL DEVELOPMENT FOR ELECTRICAL MOTORS

As described in the above parts the competitiveness of the innovation for motor applications depends generally on the designs. In any case, expanding SMC's material presentation normally increases the advantages of utilizing the SMC. Over the last 10-15 years huge material upgrades has been accomplished and the improvement is as yet progressing. Projects that were dismissed in the past may now be acknowledged because of the material improvements.

Contrasted with overlay SMC has higher DC-losses (yet lower eddy-current losses) which should be viewed as in the design in many cases. Therefore, diminishing the losses is significant to increase the competitiveness of SMC in electrical motors. The electrical resistivity of the SMC material gives an indication on the eddy current losses.

Losses are significant for motor applications and the second significant property is the B-H characteristics.

Luckily, the B-H characteristics have likewise further developed which implies that higher force densities and additionally lower Cu-misfortunes can be acquired.

One more vital property of SMC material is its mechanical strength. Since SMC materials isn't sintered lower strength are ordinarily accomplished which should be viewed as in the design stage.

The material advancement of SMC materials has prompted materials with fundamentally expanded performance like lower losses, higher permeability and expanded mechanical strength. These enhancements increment the competitiveness of innovation and the improvement proceeds.

For fruitful execution of SMC in electrical machines 3D-designs are vital. Instances of motor topologies that suite the innovation is TFM/Claw pole, AFM and direct machines.